ToyotaTacoma4Ever

New Member

- Joined

- Oct 11, 2012

- Messages

- 614

- Reaction score

- 0

Not sure if I would go 167 in the Honda. Nice job on that engine. Are you weighing all the rods and pistons ?

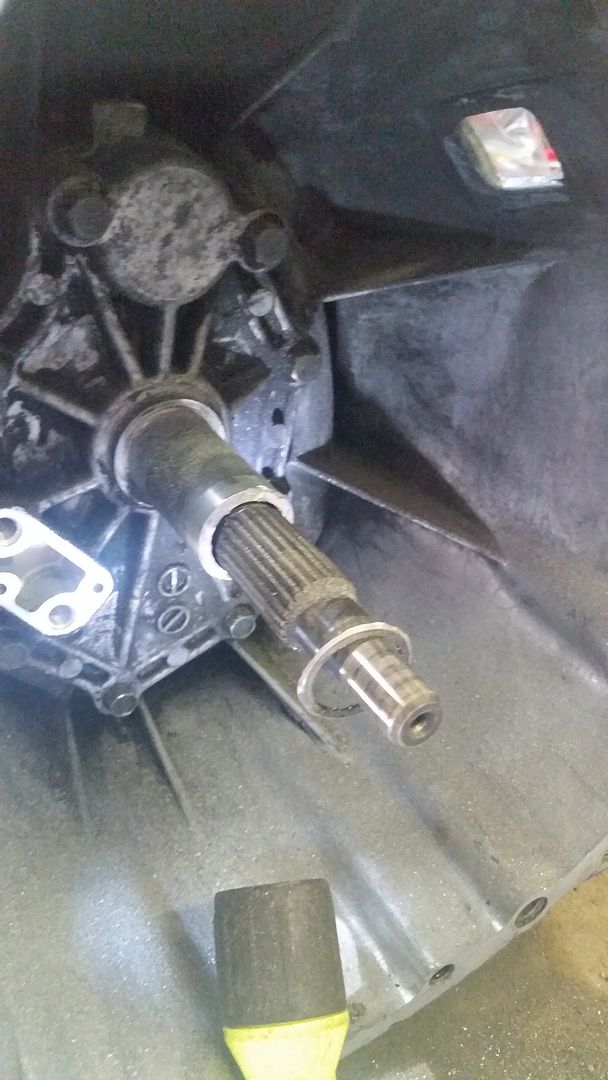

No i never did weigh any of my pistons and rods, The shop i brought it to weighed them and balanced everything accordingly

Last edited: